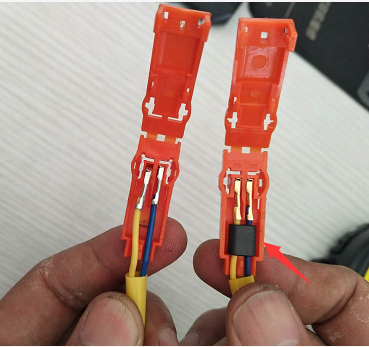

First point: LH side is Archer one, our pin is copper coating by silver. And others is use the normal copper.

2 different point

The connecting wiring, Archer we use is like OE, temperature resist up to higher 105 C, lower – 35 C like the LH side one in the picture.

The competitor one is use the normal type. pool quality.

3rd different point.

The connector we use with an extra magnetic holder like OE , Archer one is the picture RH side

And our competitor one is like the LH side of the picture, nothing protect, just pin out.

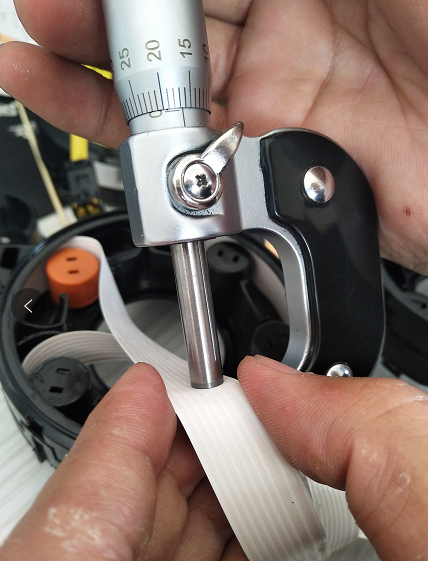

4th point

The socket we use like the RH side one, with one lock position, to secure the locking position in right position, will not lose.

The ligh yellow one at LH side are Archer competitor one, without this lock gap, easy to lose, and will have no function.

5th point

The RH side is Archer one, we do like 100% OE, use the insulation tape to close the wiring, enausre no moisture goes in, cause the rust, once rusty start, the resist wrong, will have no function.

The LH side are the competitor. Simple one.

6th point

Our wiring like the RH side one, is high grade wiring, temperature resist reach 105C.

The LH side are our competitor one is use the 80 C middle class wiring.

7th point.

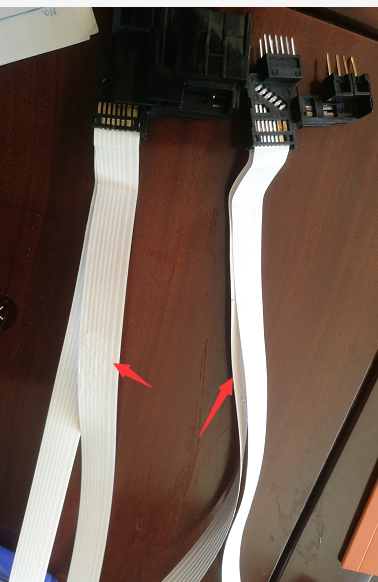

The main flat wiring we are using is like OE think less 0.21mm, like the lower picture one.

Our competitor one is use the 0.17mm for normal computer use, life time is much shorter.

8th point.

Turn the clock spring, our one is very silent, top and bottom plastic position is close very well, no noise.

Our competitor are big gap in the top and lower plastic parts, easy to lose, and when you turn you will heard noise, and that easy to lose when steering wheel turn.